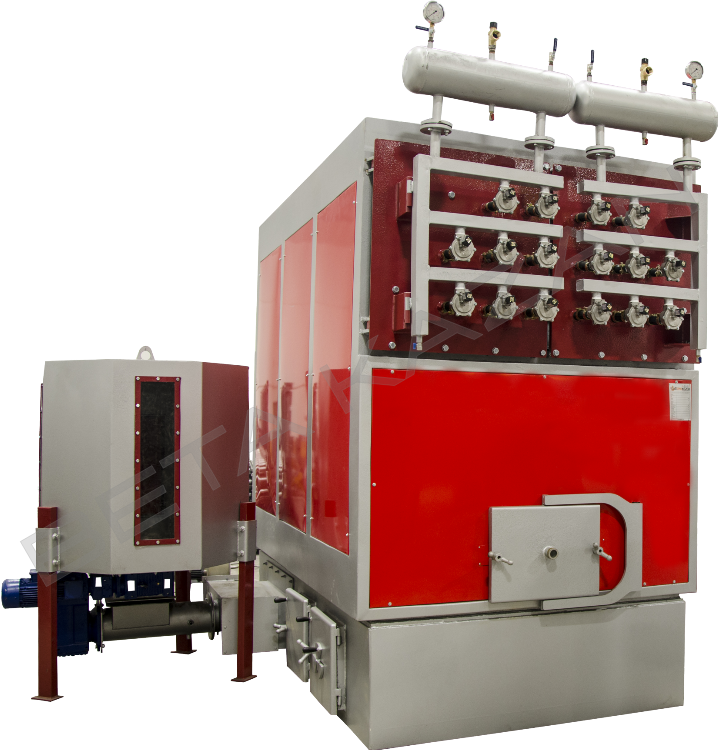

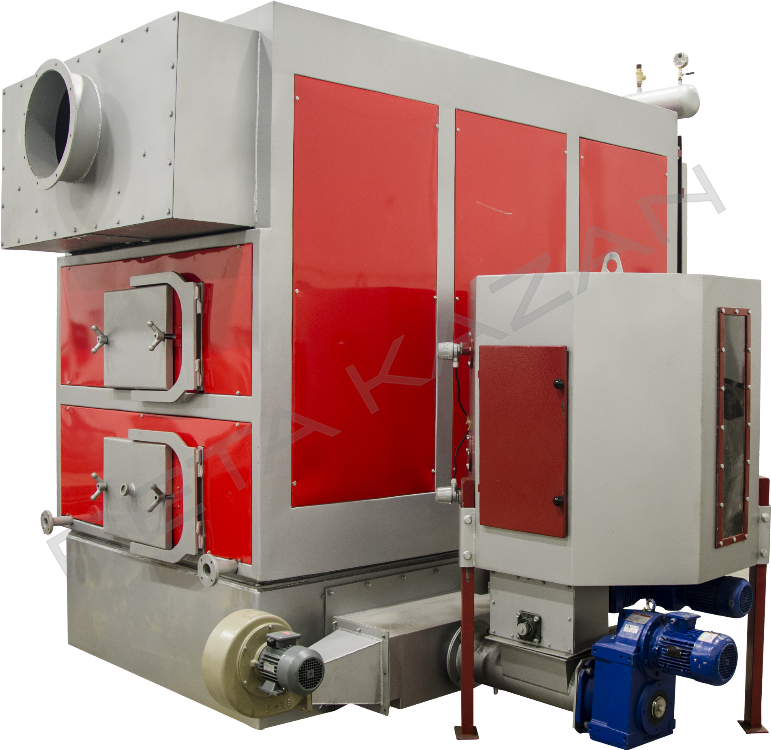

BCF Model

With chip fueled boilers, cheap and safe energy (hot water, superheated water, hot oil, steam) is obtained from factory wastes that have no economic value which are released as a result of manufacturing in your business such as pieces of wood, wood chips, MDF powder and paper.

Chip fueled boilers can burn extremely moist chips efficiently with their high mechanical durability, large combustion volume, and high alumina refractory-lined combustion chamber. The refractory material provides the high ambient temperature and thermal radiation required for combustion.

In order to reduce CO (carbon monoxide) emission, complete combustion is ensured by supplying secondary air to the combustion chamber from suitable points.

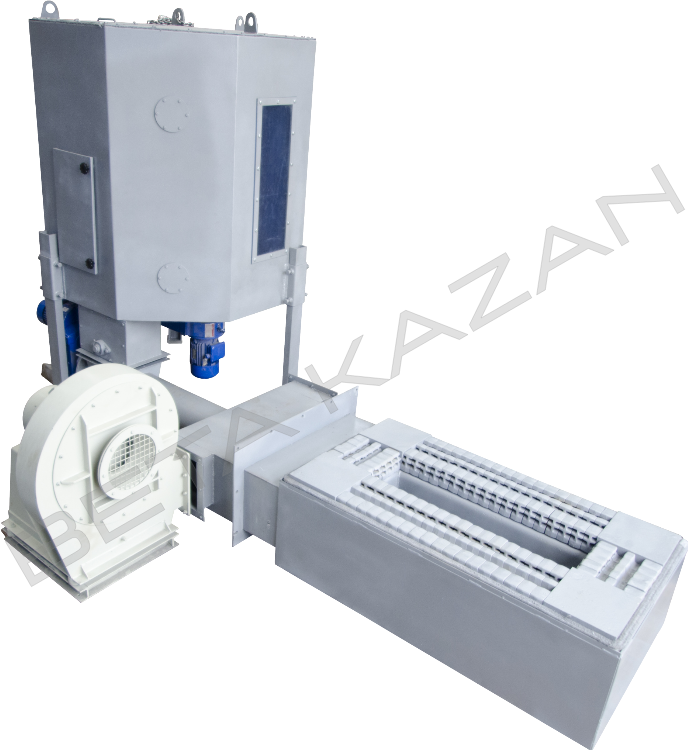

There is also a cover for manual loading of large pieces such as pieces of wood, etc…. The chip is transferred to the stocking screw with a feeding capacity adjusted by the frequency inverter rotary valve located under the bunker.

Chips are transported to the combustion chamber via the stocking screw and is burned there.

The combustion chamber is equipped with cast grates with special cross-sections and air nozzles.

An effective combustion is achieved by pulverizing the chips with the pressure effect created by the air pumped through channels and the cast grate nozzles into the combustion chamber using a fan.